Company Profile

Shandong LaiGong Machinery Manufacturing Co., Ltd. established in 1998s, has been well-known as a Chinese leading compact construction machinery manufacturer. It has been engaged in R&D and manufacturing of construction machinery for more than 20 years with a number of core patents in the field of compact machinery.

LaiGong conducts business management according to the organizational structure of the group business division with Group headquarters, Lai Gong International Division, mixer truck division, excavator division, special equipment division, and construction vehicles Division. It has 4 main modern manufacturing factories with a total area of 200,000 square meters.

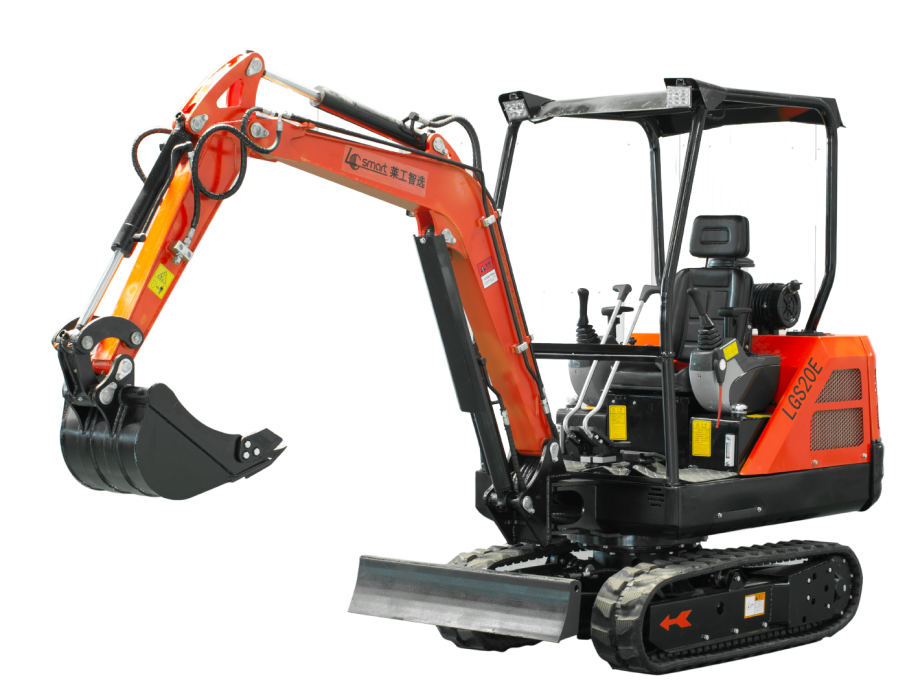

Product line includes: Wheel loaders, Self-loading mixer, Excavators, Forklifts, Tricycle, dumper trucks, etc.

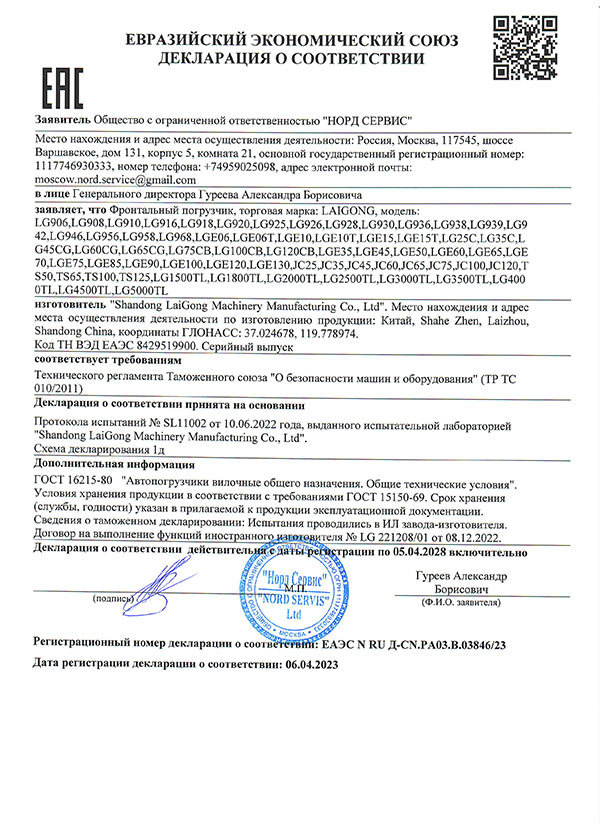

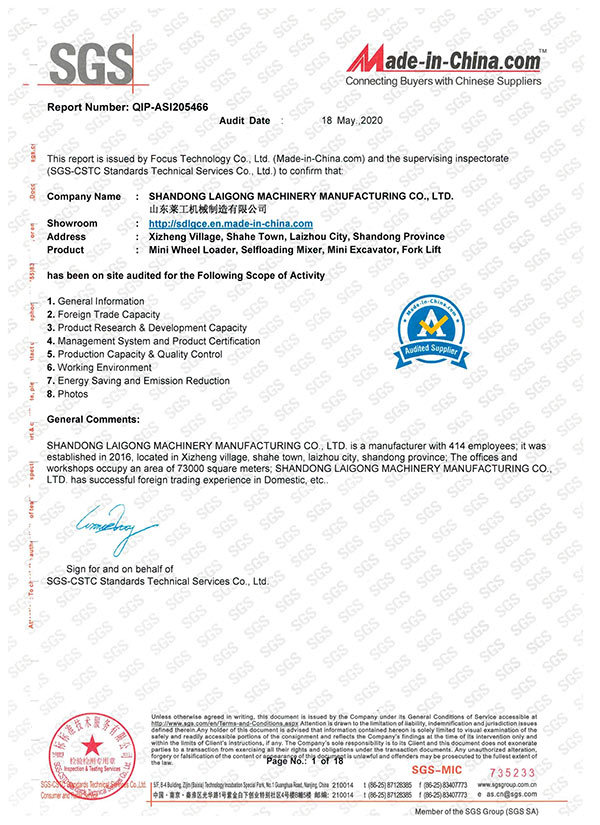

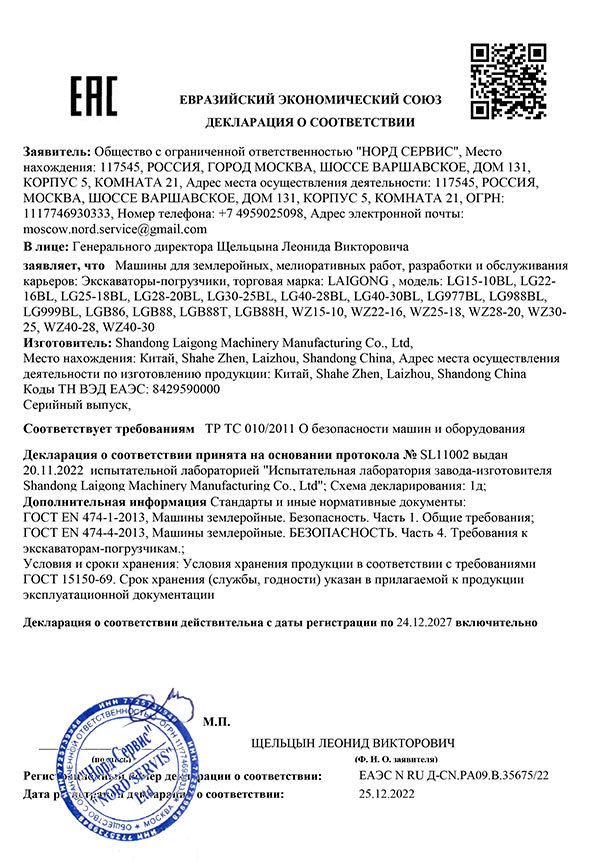

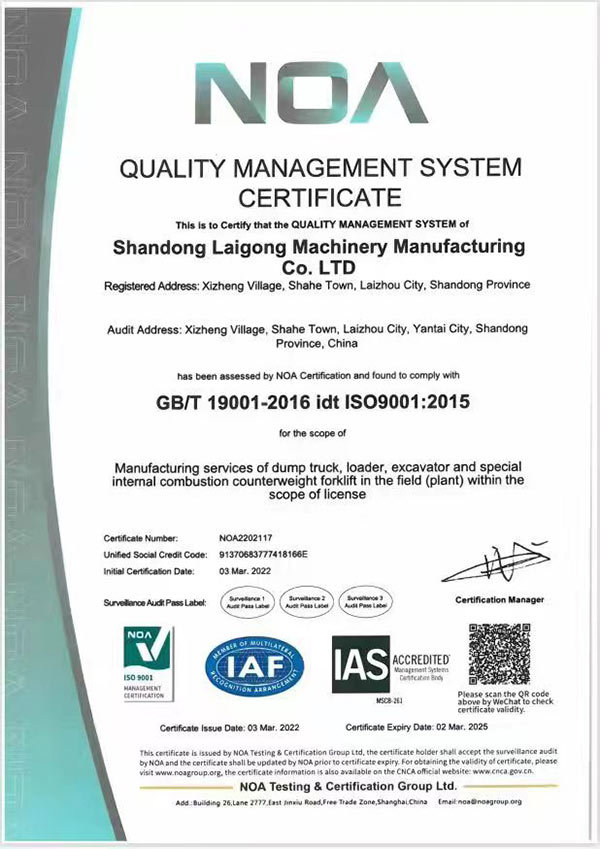

“LaiGong” products have been deeply rooted in the hearts of the people for many years and are trusted by users. Obtained a series of national and international certificates, such as ISO 9001:2008, CE, EAN etc. There are more than 400 sales and service outlets worldwide, a perfected the international market layout globally.

Established in 1998s

Construction machinery for more than 20 years

It has 4 main modern manufacturing factories

There are more than 400 sales and service outlets worldwide

In 2010, the company was rated as "Star Enterprise of Special Industry Town in Shandong Province", and Mr. Cai, Chairman of the company, was named "Merit Entrepreneur of Shandong Special Industry Development and Construction". The company has been leading domestic production and sales for 15 consecutive years and is currently a professional manufacturer of compact construction machinery in China with a full range of product categories. The company adheres to the business tenet of "excellent quality, integrity-based" and creates value for customers. Shandong LaiGong will build a brilliant career with you.

development path

Company Culture

Explore engineering technology

We are industry-oriented, adhere to good visions without distraction, focus on engineering and technical equipment and related applications, making moderate extensions, relying on bit by bit innovations to create a better future of "Top Everest" for global industry with intelligent manufacturing quality.

Unique creativity for special value

We manage to create differentiated core competitive advantages, integrate research, development and service resources with customer-focused theories, and form composite capabilities with reliable quality, leading technology, and environmental high efficiency which can create value for customers and help them to achieve success.

One stop solution

We provide to our customers with not only leading-edge products, technologies, services, but a holistic solution to diverse solutions to continuously create value for customers and help them to have successful career.

For global engineering construction and sustainable development

Our presence is to better serve the global project constructions. As one of the corporate citizens, we deeply concern about the sustainable development of human society and are committed to create a better world.

Global Trustworthy partner

Committed to continuously meet the demands of our customers and partners globally, we regard to help them to success as the basis of our survival and development. We are committed to meet diverse demands of our customers with a wide availability of products, technologies, services and solutions, to realize reality and valuable requirements from our customers’ point of view with genuine enthusiasm, dedication and continuous innovation and to win trust and friendship from our customers.

World-class enterprise

Build Laigong into a world-class enterprise with international sales team, international leading technology, international management level, international corporate culture and international brand influence.

Our Strength

Software and Hardware Strength

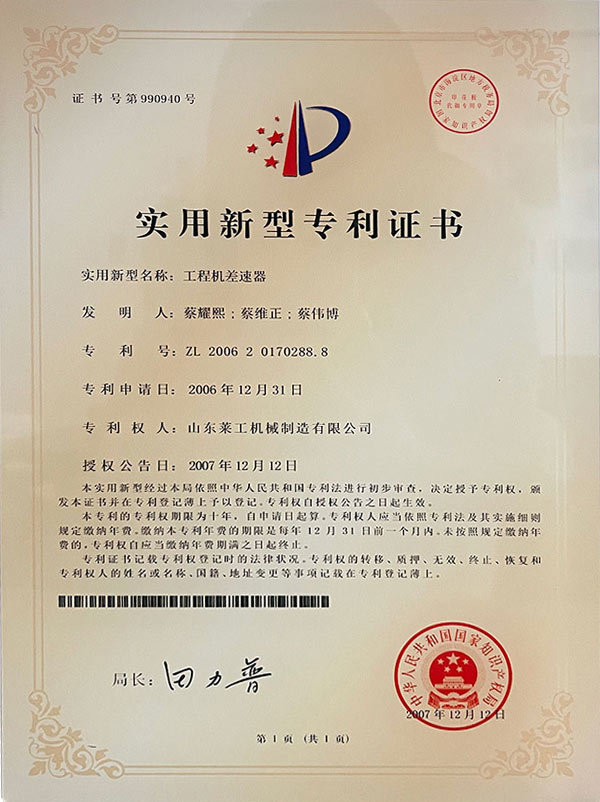

Patents and Intellectual Property Protection

Patent

Patented gearbox technology for loaders, saving 25% fuel, increasing transmission efficiency by 20% and decreasing working temperature by 10℃. Loader lateral rollover warning technology. Rough terrain forklift front and rear articulation and unibody technology patent. The whole truck or components have FOPS/ROPS related certification requirements. Hot product line, can meet the Euro V, EPA emission regulations certification.

Intellectual Property Protection

LAIGONG always adheres to the development concept that technology is the first productive force, and has continuously invested in R&D over the years, while cooperating with a number of well-known domestic universities. And constantly strengthen the protection of intellectual property rights, to protect the interests of LAIGONG and partners.

R&D and Design Center

01

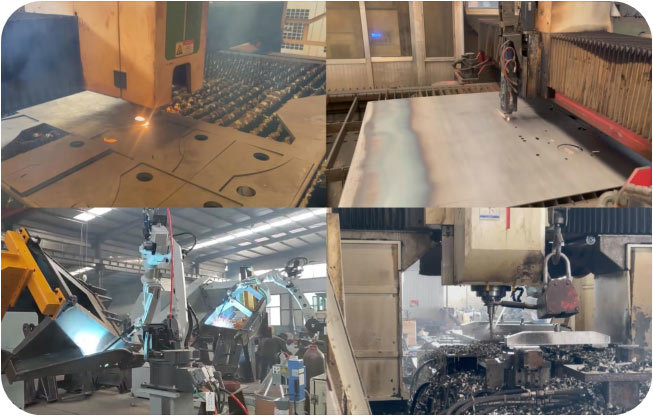

List of Equipment

4 large laser cutting machines

20 lathes

8 CNC milling machines

12 fully automatic welding robots

2 spray painting and drying lines

10 assembly lines for complete vehicles

02

Detection Capacity

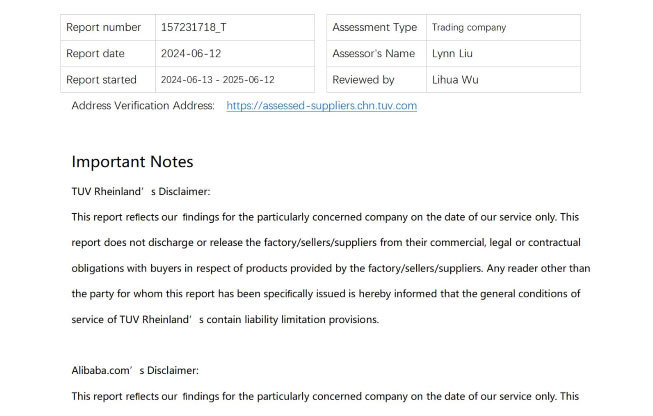

LAIGONG maintains a year-round relationship with SGS certification in Switzerland, and all of the company's models are certified for compliance when they come off the production line. At the same time, we maintain cooperation with TÜV Rheinland of Germany, which is at the leading level of the industry in terms of product safety and environmental protection.

03

R&D Center

Relying on more than 20 years of experience in the field of construction machinery, LAIGONG has built a specialized innovation system with high-level talents as the core. The team has realized 23 patented technology achievements. Adopting the whole life cycle control mode, it provides solid technical support for the annual production capacity of over 40,000 units.

Full Chain Capability

Technical

Dual-Track R&D Team

In the field of technology research and development, LAIGONG realizes the synergy between technology breakthrough and industrialization through the dual-track strategy of “basic innovation” and “market-driven”. LAIGONG focuses on forward-looking technology research, closely matches the needs of user scenarios, and carries out rapid iteration to address the pain points of construction machinery operation efficiency and energy consumption control, ensuring that the product technical indexes are ahead of the industry standard.

Technical Cooperation and Exchange

LAIGONG realizes the synergistic upgrading of the industrial chain through joint technical research and development with leading enterprises in the industry. Relying on the technology research platform built with scientific research institutions, LAIGONG focuses on cutting-edge fields such as intelligent control system. As a result, LAIGONG's differentiated competitive advantages in the field of small and medium-sized construction machinery are obvious.

Talent Team Building

1. LAIGONG establishes strategic cooperation with top domestic headhunting organizations to introduce mechanical engineering experts and intelligent technology leaders with development capability.

2. LAIGONG has established “Intelligent Equipment Research Institute” with Shandong University and other universities, and has jointly cultivated 42 professional and technical talents with master's degree or above in the past three years.

Production

Large scale manufacturing capability

The five specialized factories of Laigong cover an area of over 300000 square meters, with a total of twelve advanced production equipment intelligent assembly lines, equipped with high-precision machining centers and automated welding equipment, to improve production efficiency and product quality. Establish a manufacturing capacity of over 40000 units per year for construction machinery and equipment, covering multiple popular product categories such as loaders, off-road forklifts, forklifts, concrete mixers, excavators, etc.

Full cycle traceability

Full cycle traceability of the supply chain, established through the ISO 9001 quality management system certification framework, raw material batch management system and worker skill archive, to achieve full traceability from steel procurement to finished product assembly, ensuring that the traceability response time of key components is controlled within 2 hours. And can provide quick and comprehensive solutions for product after-sales.

Quality control system

Adopting a dual inspection mechanism of process level quality control (IPQC) and finished product factory inspection, quality gate control points are set up in 12 core processes such as welding and final assembly, and final inspection is carried out using measuring equipment such as coordinate measuring instruments. The first-time acceptance rate of products remains stable at over 99.5%. This production system effectively supports the enterprise's business philosophy of "quality first" and provides a solid guarantee for products to enter international markets such as Europe and North America.

After-Sales Differentiation

Equipment Lifetime File System

Based on internet technology, LAIGONG establishes the unique identification code of the equipment, integrates the operation data, maintenance records and working condition data, and forms the lifelong electronic file which is dynamically updated. The system supports global users to access the equipment factory configuration and parts replacement at any time, providing data support for preventive maintenance.

Gridded Regional Service Centers

LAIGONG has set up 7 first-class after-sales bases in core markets such as Asia-Pacific, Europe and Russian-speaking regions for different construction machinery application scenarios around the world, and is equipped with localized technical teams and standardized spare parts warehouses. LAIGONG also develops special maintenance programs for typical working conditions in the region (such as corrosion protection in tropical rainforests, high temperature in deserts, cold adaptation, etc.).

Remote Support System

A perfect after-sales service team consists of 10 senior engineers. Customers can obtain fault analysis, maintenance guidelines and spare parts matching services online through the exclusive after-sales personnel, and under complex working conditions, the team of experts supports 72-hour non-stop consultation, so that the time limit for solving routine problems can be increased to within 24 hours.